-

Instead of manual work,Passion storage adopts manipulator to store and reclaim material to save manpower; With one-to-one intensive storage, it can not only replace traditional shelves for saving space,but also realize accurate control;

Passion SMT intelligent storage resolves the reel information through industrial vision technology when material was stored; and deliver automatically, efficiently and accurately through the integration of software system when material was reclaimed

Material storage shelf

Anti-static frame design, support reel,bulk materials (e.g. bags), trays etc

Access machanism

Robots pick and store materials accurately with a fast execution speed in 3D

Batch buffer hopper

When multiple reels need to be accessed, the buffer hopper can complete the operation at one time

Business logic algorithm

FIFO algorithm, optimal access path algorithm, similar material aggregation classification algorithm

Electrical control system

The electrical equipment and mechanism that controls the whole SMT intelligent storage system, including servo system, PLC, etc

Material identification system

Recognize 1/2D bar code and RFID tag, identify stored materials, reconfirm the materials picked

Warehouse WMS system

SMT smart warehouse management software can work independently or integrate with the existing warehouse management software

Other systems can be integrated

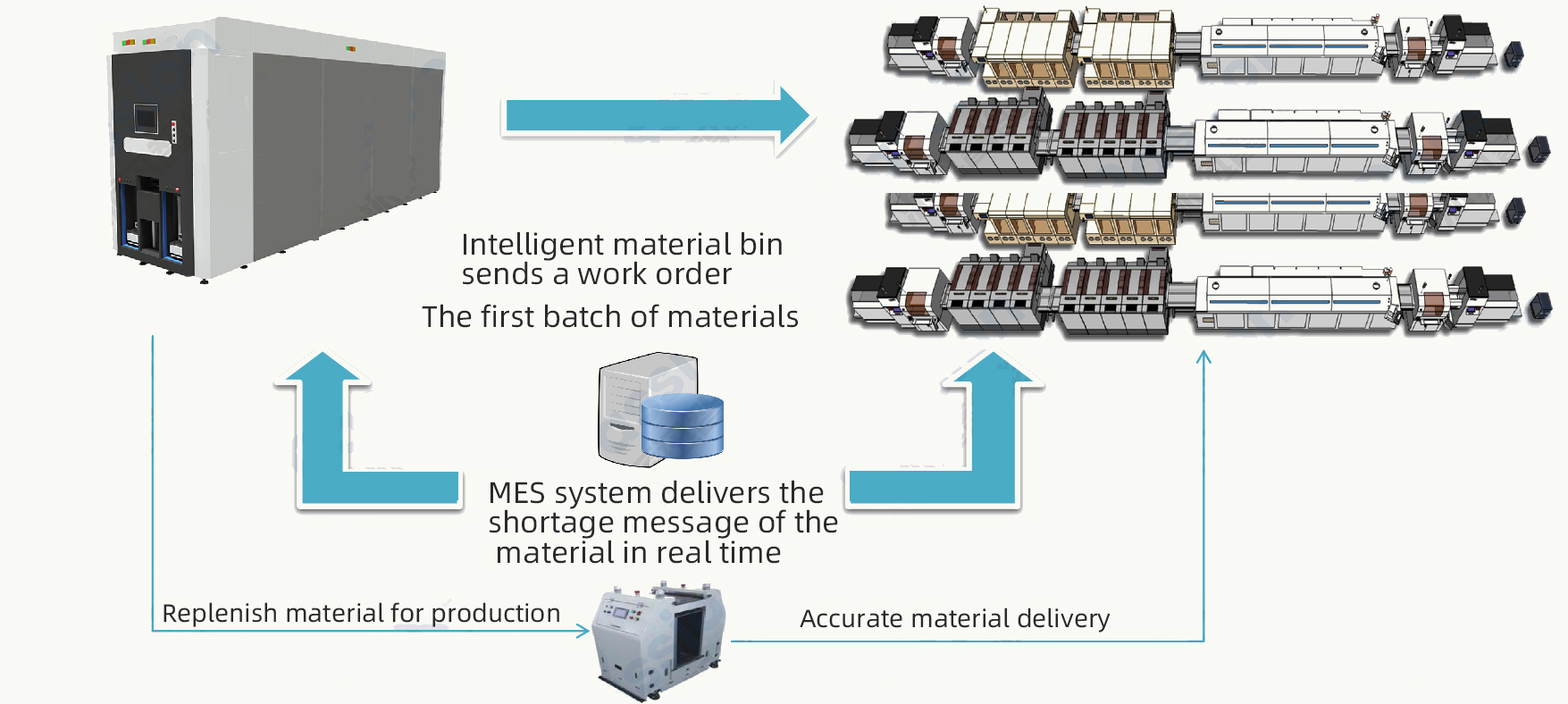

Integrate with SFIS/MES, AGV trolley, LES to realize automatic SMT WIP inventory distribution and establish JIT mode

Prepare materials for the first batch quickly according to the work order, and then replenish material according to the takt time, saving manpower and time for material preparation and searching; keep no excess reels on the production line and eliminate the risk of wrong material

Put the reel into the boom - enter the smart material bin - scan the barcode automaticly - the manipulator will put the reel into the rack

The smart material bin receives the delivery instruction -- the manipulator picks the reel from the rack -- put it into the delivery waiting belt -- transfer the reel to the delivery port

| SN | Parameter | Specifications / Functions |

| 1 | Dimension | H3200mm, W1950mm, L8600mm (can be customized) |

| 2 | Storage capacity |

allow reels of 7-inch or 13-inch. The size can be specified. 7-inch 8mm, 6000 pcs |

| 3 | Average access time | ≤15s |

| 4 | Access method | Access materials automatically with a manipulator.AGV can be added to connect and the delivery port and send to the specified discharging point |

| 5 | Anti-static level | Material of the contact surface with reels (belt line, manipulator) 106Ω-1011Ω |

| 6 | Emergency stop function | Emergency stop switch with a protection cover to allow stop at any time in emergency, emergency switch |

| 7 | Temperature and humidity monitoring function | Real-time monitoring and display the temperature and humidity in the material bin |

No. 28 Heshun Road, Suzhou Industrial Park, China

No. 28 Heshun Road, Suzhou Industrial Park, China  +86 13451983657

+86 13451983657  sales@passioniot.com

sales@passioniot.com