-

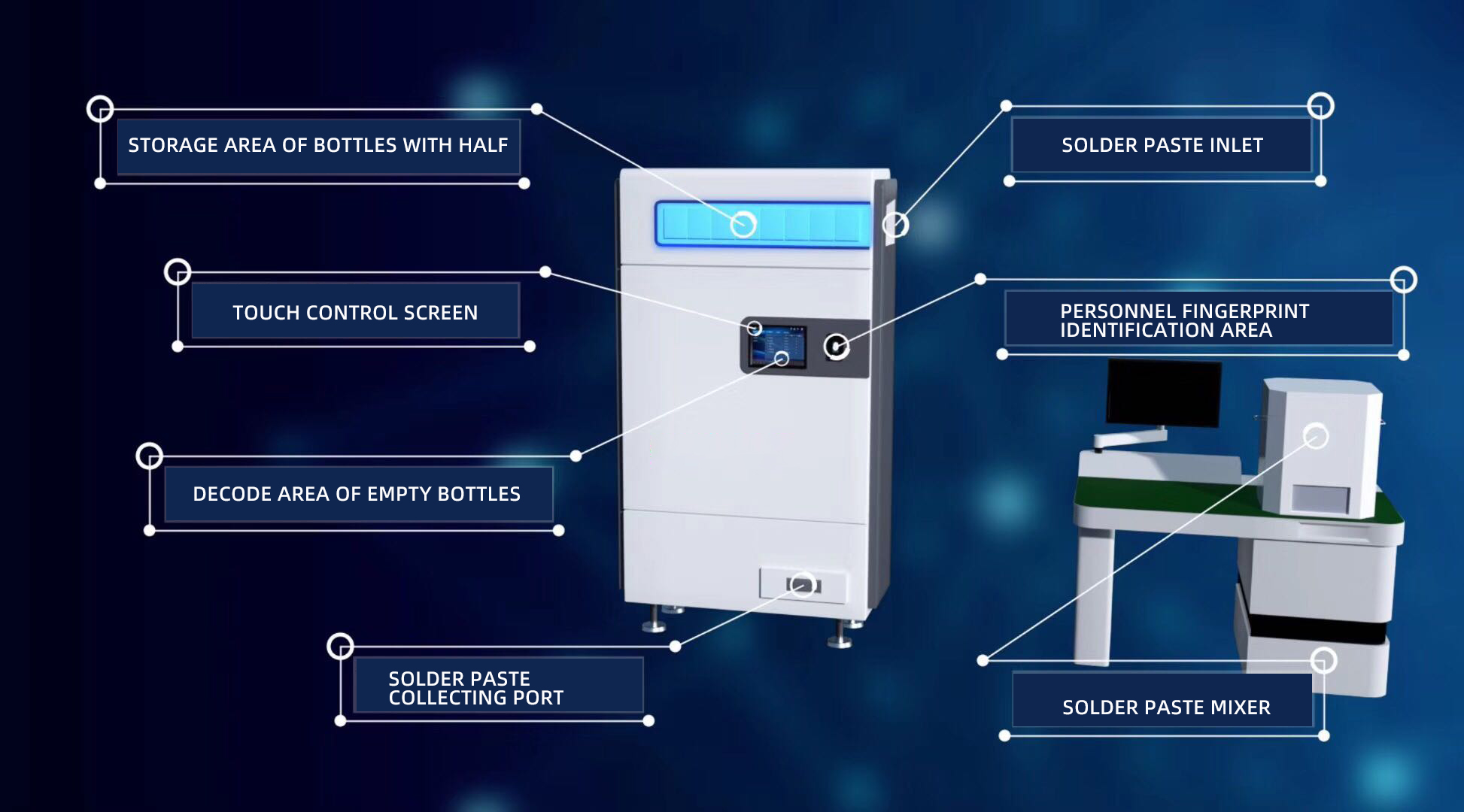

Intelligent solder paste storage and warming cabinet can automatically realize all the functions including cold storage, rewarm for use, automatic mixing, etc.

Solder paste feed - scan code - enter the refrigerator - scan code-enter the rewarming area - rewarm- scan code - mix - scan code - deliver - scan code - demagnetize

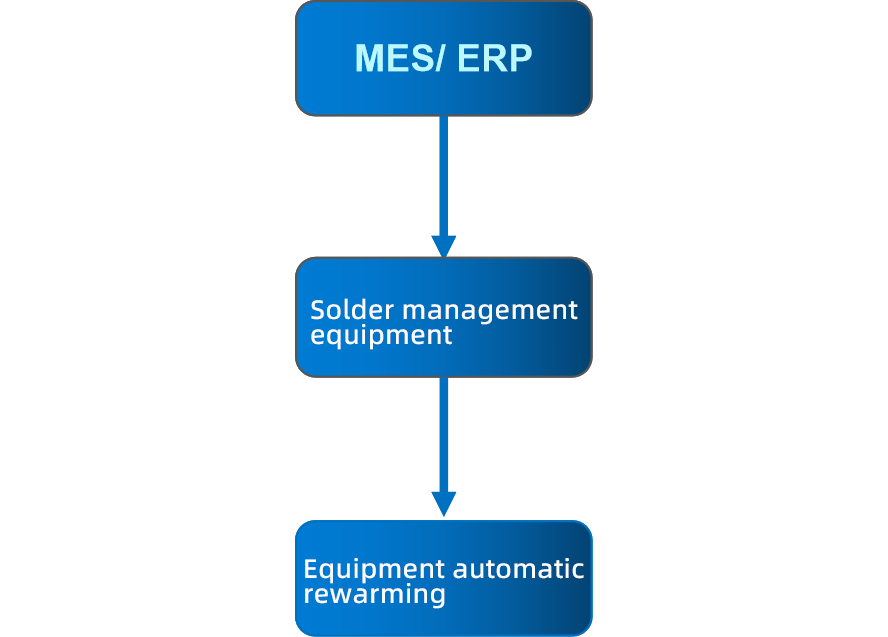

Collecting materials against production work order:5W1H:1.Which work order? 2. What will be collected? 3. For which production line? 4. Who receives? 5. When will it be picked up for use? 6. How many materials will be picked up for use?

Solder paste equipment collection information:5W1H:1. Which production work order? 2. What solder paste will be picked up for use? 3. For which production line? 4. Who receives? 5. When will it be picked up for use? 6. How many materials will be picked up for use?

Execute and feedback:1. Automatically warm at the scheduled time; 2. warm the specified amount; 3. When the amount is insufficient, feedback to the MES system automatically to replenish lineside warehouse stock 4. The materials are rewarmed; feed back to the MES system and users automatically 5. Send timeout alarm in case of overtime or abnormal situation 6. The materials are rewarmed and personnel matches to receive corresponding solder paste 7. Real-time temperature records of the rewarming environment

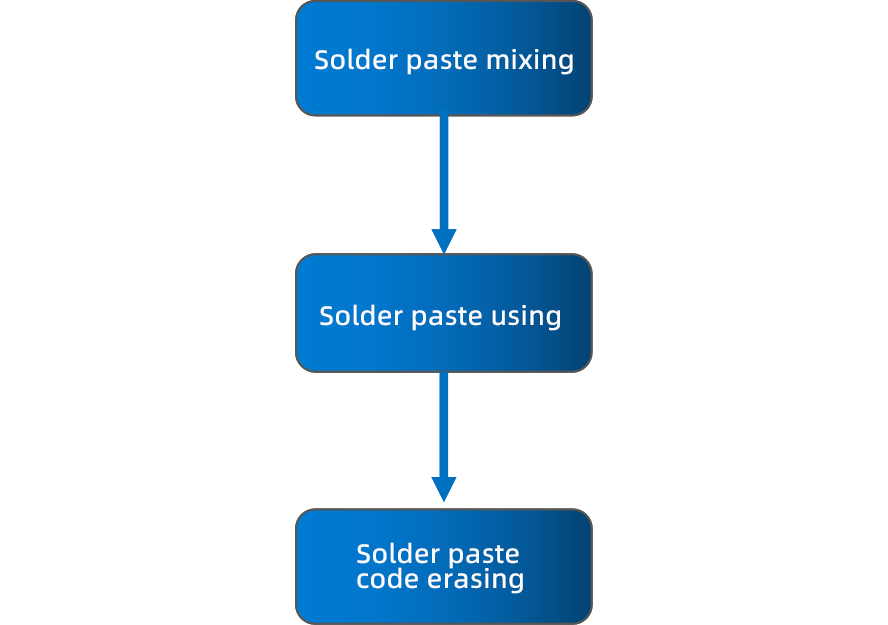

Docking with stirring equipment: 1. The mixing of the solder paste shall be completed within the specified time after being collected; 2. The solder paste mixer is integrated with the solder paste storage device; 3. Stirring time and personnel information feedback equipment

Solder paste use process monitoring (MES) : 1. Work order requirements and solder paste matching (error-proof); 2. Record the use time of solder paste and match the quantity with corresponding work orders; 3. Record solder paste users 4. Return unused solder paste to the material bin

Execute and feedback:1. Return used solder paste boxes to demagnetize(MES); 2. Return the unused solder paste to the solder paste smart cabinet to demagnetize; 3. The equipment records the return time and feeds back to MES system about unspent solder paste shelf life; 4. After the code elimination is completed, the material requisition form is closed

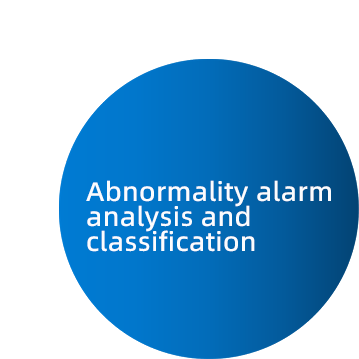

Quality warning:solder paste quality warranty expiration warming; warning before quality warranty expiration

Permission warning:unauthorized appointment reminder; Unauthorized use reminder

Integrated warning: Solder paste mixing time reminder; MES reminder; Kanban reminder; Mobile APP reminder

Timeout warning:use of timeout warning; return timeout warning; reminder before completion

Temperature warning: High temperature alarm; Low temperature alarm; Power failure warning

Material shortage warning: Equipment material shortage reminder; safety stock warning

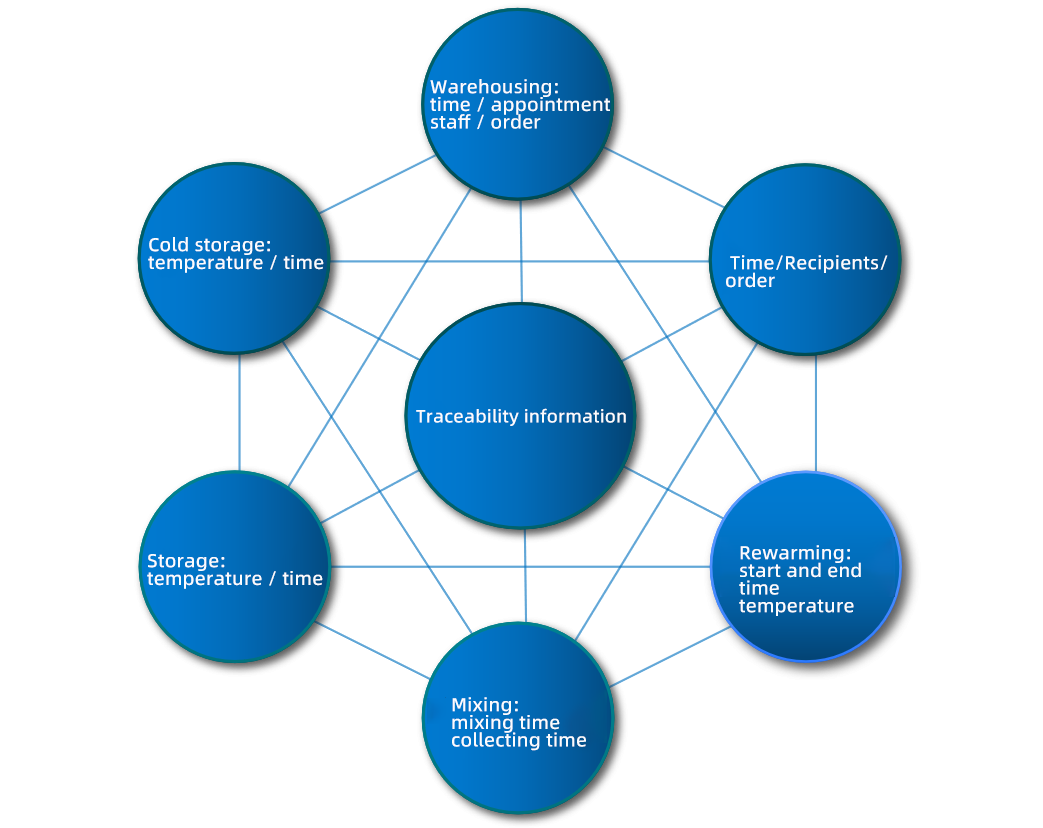

Forward traceability: Trace by the solder paste barcode information;trace storage/rewarming/mixing/Receiving;personnel/time/temperature/work order/product;

Reverse traceability:trace by the finished product barcode information;trace solder paste storage/rewarming/mixing/using;personnel/time/temperature/order/batch/supplier

| CATEGORY | PRODUCT PARAMETERS | |||||||

| Model |

Quantity of refrigerated goods* |

Rebound quantity |

Mixing mode | Dimensions | Power | Weight |

Packaging mode |

Others |

| PSW-50 | 56 | 5 | Automatic | L1100*W1300*H1950MM | 2500W | 1000KG |

500g bottle solder paste |

|

|

PSW-60 |

165 | 40 |

Automatic |

L1460*W1490*H1950MM |

3000W |

1200KG |

500g bottle solder paste |

Feeding amount per time: 28 bottles |

|

PSW-60L |

330 | 55 |

Automatic |

L1860*W1490*H1950MM |

4000W |

1550KG |

500g bottle solder paste |

Feeding amount per time: 28 bottles |

|

PSW-60XL |

624 | 120 |

Automatic |

L2840*W1690*H2350MM |

9000W |

2450KG |

500g bottle solder paste |

Feeding amount per time: 20 bottles |

|

PSW-7020 |

70 | 15 |

Automatic |

L1860*W1490*H1950MM |

4000W |

1550KG |

500g bottle solder paste |

|

| 225 | 70 | Not required |

|

100g cylinder solder paste |

|

|||

No. 28 Heshun Road, Suzhou Industrial Park, China

No. 28 Heshun Road, Suzhou Industrial Park, China  +86 13451983657

+86 13451983657  sales@passioniot.com

sales@passioniot.com