Blockbuster! Passion’s Warehousing Solution Was Reported by CCTV News

CCTV News Network Program has broadcasted the operation video of Passion’s intelligent storage equipment

100% delivery

Help top 500 giants to throw themselves into investment

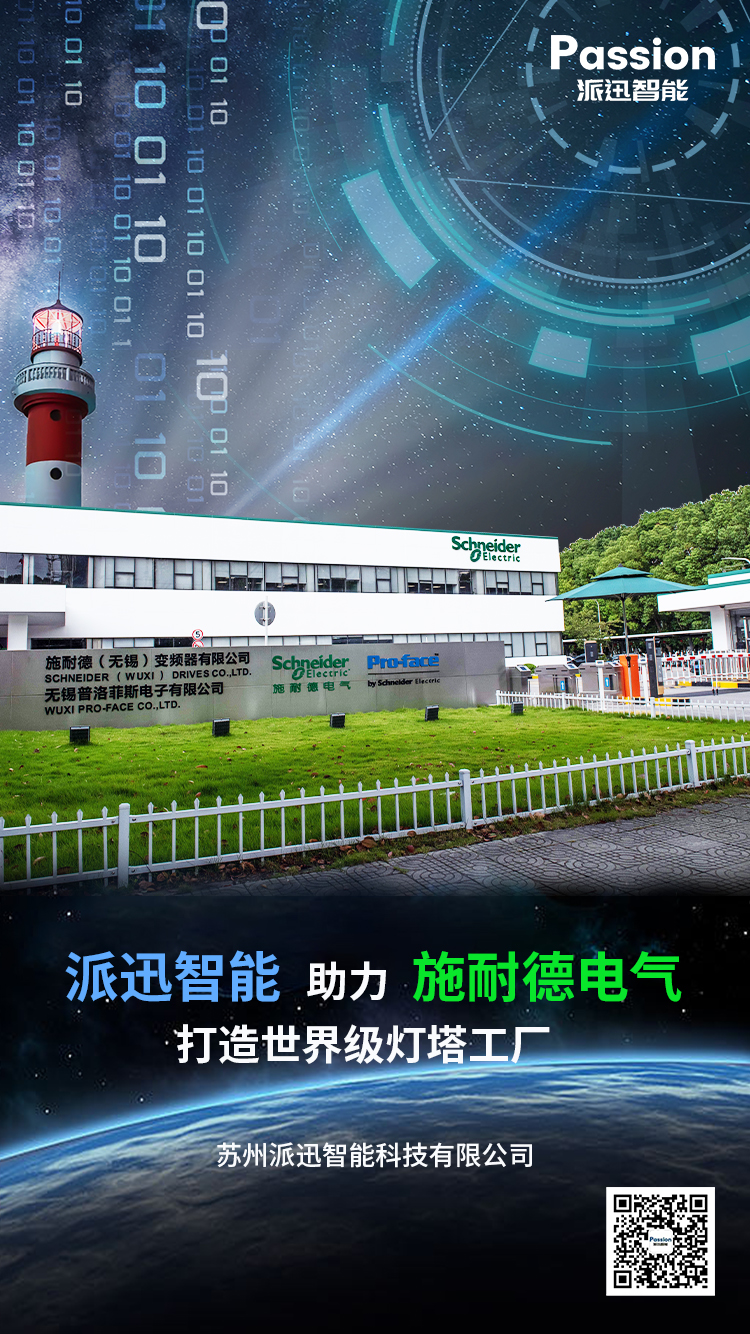

On the evening of May 21, the CCTV News Broadcast broadcast the news that "Strong service, excellent environment, and foreign investment continue to be optimistic about China's development prospects". During the speech by Yin Zheng, president of Schneider Electric China, the video showed the intelligent storage operation scene in the "Lighthouse Factory" successfully built by Schneider Electric with the help of Passion.

PSW series intelligent storage equipment, Passion’s representative product reported by CCTV News, was delivered to Schneider Electric Wuxi Factory in 2017. Since being put into use, the equipment runs smoothly, and performs excellently, with features such as intensive warehousing, automatic pick-up, high material flow efficiency, high space utilization and consistency between materials and accounts.

The customer’s field reported is Schneider Electric (China) Wuxi Factory, and is both Schneider Electric’s first end-to-end “Lighthouse” in China and the fourth “Lighthouse Factory” built by Passion successfully.

AI+Warehousing

Original “accelerator” energizing the global economy

Currently, the global economy is undergoing a complex transformation. Facing challenges brought by COVID-19, population aging, unstable supply chain and excessive inventory of some commodities, the global industry, the global economy is in a difficult situation: for the ways to stop work without stopping production, avoid sluggish materials/inventory and flexibly and efficiently respond to various customer demands... the digital intelligent transformation has become an essential “accelerator” for industrial recovery.

Schneider Electric Core Factory - Wuxi Pro-face Electronics Co. Ltd.

Schneider Electric is one of the world’s top electrical companies, and one of industrial pioneers in France, as well as one of Fortune 500 companies.

Wuxi Pro-face Electronics Co. Ltd. is the only manufacturing center with electronic ability among Schneider Electric’s 23 factories in China, characterized with assembly and production of small-batch and multi-variety products.

Upon the intelligent transformation and upgrading, Schneider Wuxi Factory has: increased the on-time delivery ratio by 30%, shortened the time to market by 25%, reduced the defective rate by 22% and saved the warehousing space by 52%...

In September 2021, Schneider Electric Co., Ltd. Wuxi Factory was successfully selected into the “Lighthouse Factory” of the World Economic Forum with its outstanding achievements in digital transformation.

When accepting an interview, Zhang Kaipeng, a Senior Vice President of Schneider Electric and Director of Global Supply Chain (China) said that “Wuxi Factory, as Schneider Electric’s first “Lighthouse Factory” in China, is a demonstration project with digital reconstruction of end-to-end value chain.”.

Before upgrading:

Currently, the market competition is increasingly inclined towards the competition of the overall industrial chain. The end-to-end efficiency increase and emission reduction are of significance for manufacturing. Before transformation, during warehousing, Schneider Electric Wuxi Factory has relatively low degree of automation, digitization and intelligent management due to a series of problems such as huge production workshop area, scattered production parts, data and information transmission dominated by paper documents and high labor intensity.

In the field, the following difficulties in management are faced:-low efficiency: diverse material varieties, long time for manpower to pick up materials, low efficiency;-fallibility: order picking based on paper documents, distribution mistake or omission easily caused, mistakes easily made;-waste: difficult check, inconsistency between materials and accounts, increasing sluggish materials;-high cost: several positions occupied for one product, difficulty in managing inventory, high requirements for personnel experience, unstable personnel.

Dream Builder for “Lighthouse Factory” - Passion

Led by technical expert team of the State Key Laboratory of Digital Manufacturing Equipment and Technology, Passion has core research and development teams which once led many intelligent manufacturing demonstration projects of the Ministry of Industry and Information Technology. The project planning and implementation team members are all from global famous enterprises and schools, with profound technical foundation and rich experience in model projects implementation.

Based on the intelligent transformation need of electrical giant Schneider Wuxi Factory, Passion has provided the one-stop intelligent warehousing solution for Schneider Electric: it gets through the "blocking" point from the warehouse to the production line, realizes the intelligent quality control of materials, early warning deployment, punctual and accurate sorting, JIT lean management at the same time, avoids the extra cost of easy error and stagnant materials caused by manual picking and inventory, and successfully reconstructs the end-to-end value chain with digitalization and intelligence

Upgrading effect:

when accepting an interview, Zhang Kaipeng, a Senior Vice President of Schneider Electric and Director of Global Supply Chain (China) said that:

Wuxi Factory has widely applied leading digital technologies, and realized the transformation and upgrading from automated factory to end-to-end whole-value chain digitalization, as well as spanned over the whole cycle from supplier management to factory production and then to delivery to users.

During the procurement, the digital supplier system ecosystem can dynamically simulate and predict the factory demand and supplier capacity in real time, realize the transparent and efficient automatic supply chain management, and increase the on-time delivery ratio of the factory by 30%.

During the quality inspection, the factory can realize the timely quality inspection, and realize the early warning to make the field failure reduced by 22% through the end-to-end cloud platform for electronic component quality risk detection and management deployed.

During delivery, the factory’s intelligent flexible warehousing solution can fully show the warehousing flexibility and efficiency improvement, and make warehousing space saved by 52%. Wuxi Factory has 2000m2 ASRS stereoscopic warehouse with more than 7000 pallet points, and it is 2 times of ordinary forklift warehouse.

'LighthouseFactory ' leader lights the way forward

The “Lighthouse Factory”, as a model of the Fourth Industrial Revolution, takes the lead in industry in terms of informatization, digitalization and intelligence, and is known as the “beacon” to guide enterprises to optimize the development strategy, innovate the technology application and improve the development quality and efficiency.

Intelligent warehousing logistics is an important component of high-end manufacturing, and the trend of "machines replace people" is inevitable.

With the flexibility and digitization of production, higher requirements are put forward for warehousing and logistics. Traditional manual warehousing, material finding, inventory and other human-dependent operation methods are not only laborious, but also inefficient and error-prone. In addition to the increasingly prominent problems of aging society, difficult and expensive employment, the intelligentization of warehousing logistics has become the optimal solution to reduce costs and increase efficiency in various industries.

Passionhas rich experience in product development and industrialization in the field of industrial robot technology and digital manufacturing. It has achieved long-term cooperation with many leading enterprises in the fields of 3C, household appliances, automotive electronics, semiconductor, military industry, rail transit, network communication, medical, aerospace, electric power and other fields, and helped many top 500 enterprises to successfully build ' lighthouse factories '. In 2021 alone, four intelligent reform projects were successfully selected as ' Lighthouse Factory ', including Midea-Shunde Factory, Foxconn-Chengdu Factory, Foxconn-Wuhan Factory and Schneider-Wuxi Factory.

In 2021, Passion Intelligent helped Fortune 500 companies to build the world-class “Lighthouse Factory” successfully.

Passion is committed to continuous innovation for promoting the intelligent transformation of industry and providing the better intelligent production and working mode for human beings. Passion will continue to cultivate intelligent storage, enabling intelligent manufacturing transformation, and actively share its “lighthouse experience” of smart warehousing and logistics to empower the world’s industry.

No. 28 Heshun Road, Suzhou Industrial Park, China

No. 28 Heshun Road, Suzhou Industrial Park, China  +86 13451983657

+86 13451983657  sales@passioniot.com

sales@passioniot.com