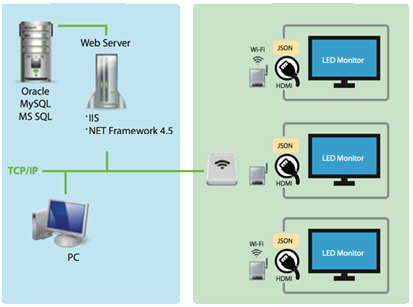

System Bus Architecture

Introduction of software function modules

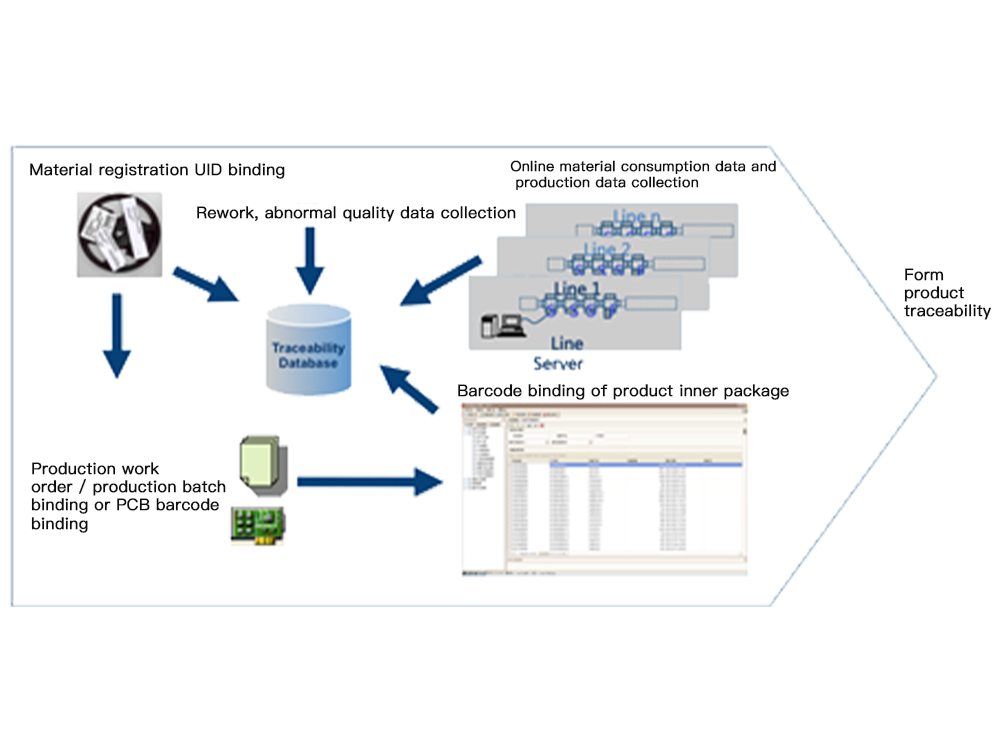

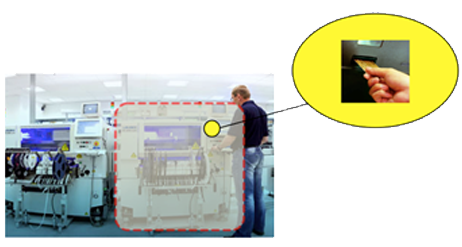

1.Production traceability module

The MES system takes comprehensive traceability management to record the mounted element information, including name, batch, date of manufacture, etc., record ID of every PCB entering the SMT machine and then combine them with the element information and production data collected before as well as quality abnormal and repair information during production to form real-time tracing data.

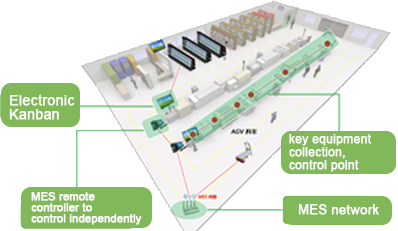

2.Production line management module

Process monitoring:

Integrate supply chain management and control system, production execution system and resource management system for a Closed-loop detection of products throughout their life cycle

Abnormal judgment:

Realize exception control throughout the process through the schedulability of execution transactions

User interaction:

Realize remote supervision and unmanned scheduling through transaction management kanban, task scheduling and job recording

3.Quality management module

Question collecting section:

Summarize product problems, equipment failures, raw material defects, etc by product quality, equipment engineers and management methods so to reflect from different perspectives

Quality control includes:

Quality control of components, PCB and other raw materials, and statistics of sluggish and expired materials; process quality control, etc

Product quality analysis:

Carry out process analysis, control chart analysis, histogram analysis, trend chart analysis and process capability analysis on the processed product parts.

Comprehensive quality determination:

Establish a quality assessment system and process standards for batch orders, and comprehensively determine the batch quality in combination with all the production process data of the field batch order.

4.Personnel management module

On-duty and off-duty collection, on-duty skill control, on-duty personnel skill display, skills assessment appointment, on-duty skill statistics, personnel skill statistics, integration of working hours to calculate personnel efficiency, and control personnel operating equipment records.

5.Automatic report production module

Equipment exception summary report, production report, abnormal loss time report, SMT production status report, equipment exception data summary report, plan achievement rate report

No. 28 Heshun Road, Suzhou Industrial Park, China

No. 28 Heshun Road, Suzhou Industrial Park, China  +86 13451983657

+86 13451983657  sales@passioniot.com

sales@passioniot.com